This is a great, cost effective way to harvest your product. Equipped with box slides, set up trays and box packing trays.

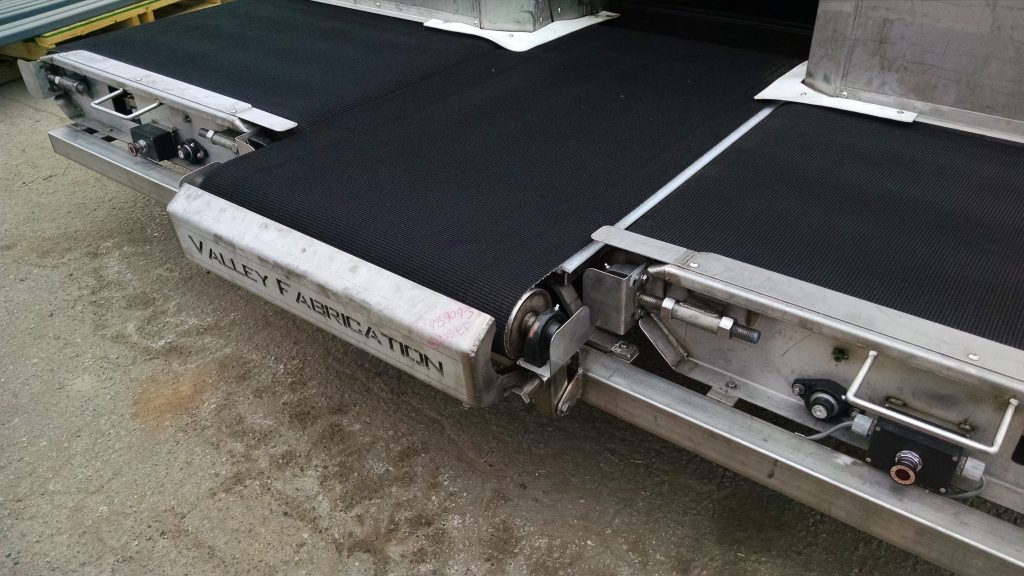

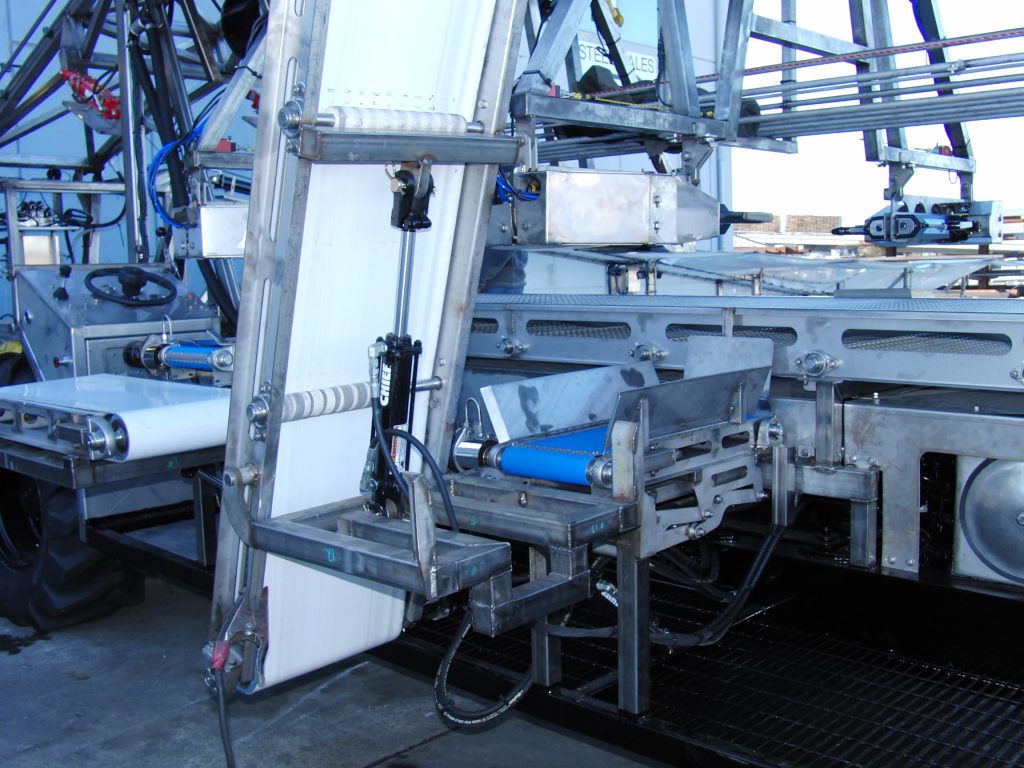

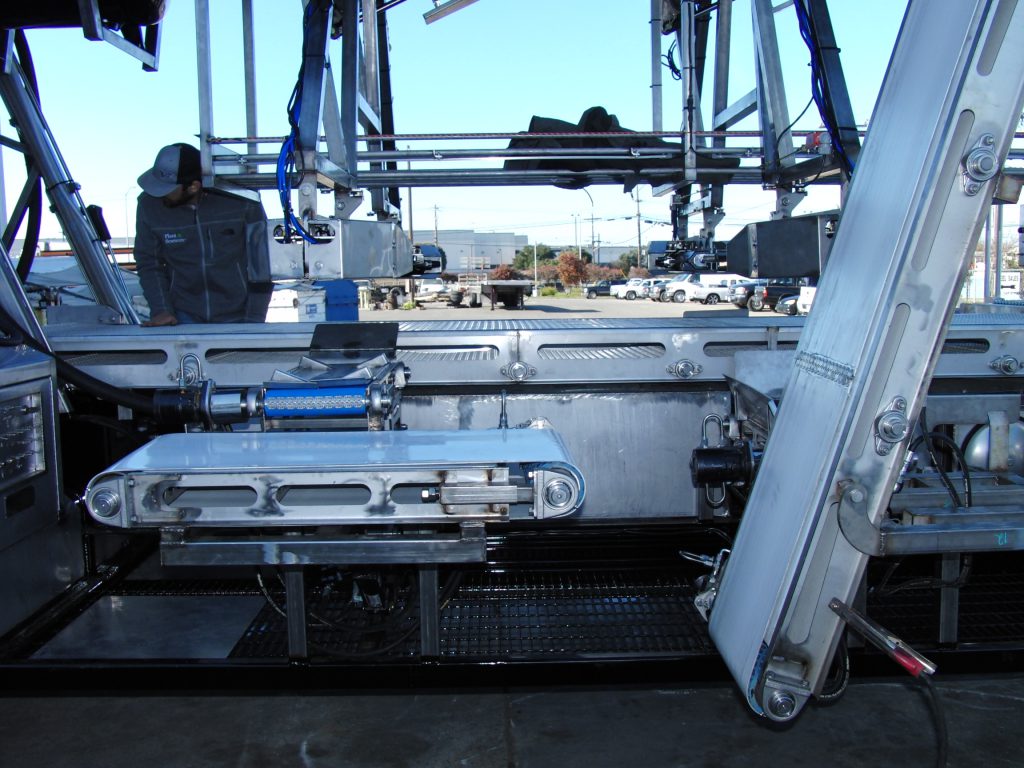

Offload conveyors on both sides for easier in field use.

Other Specs:

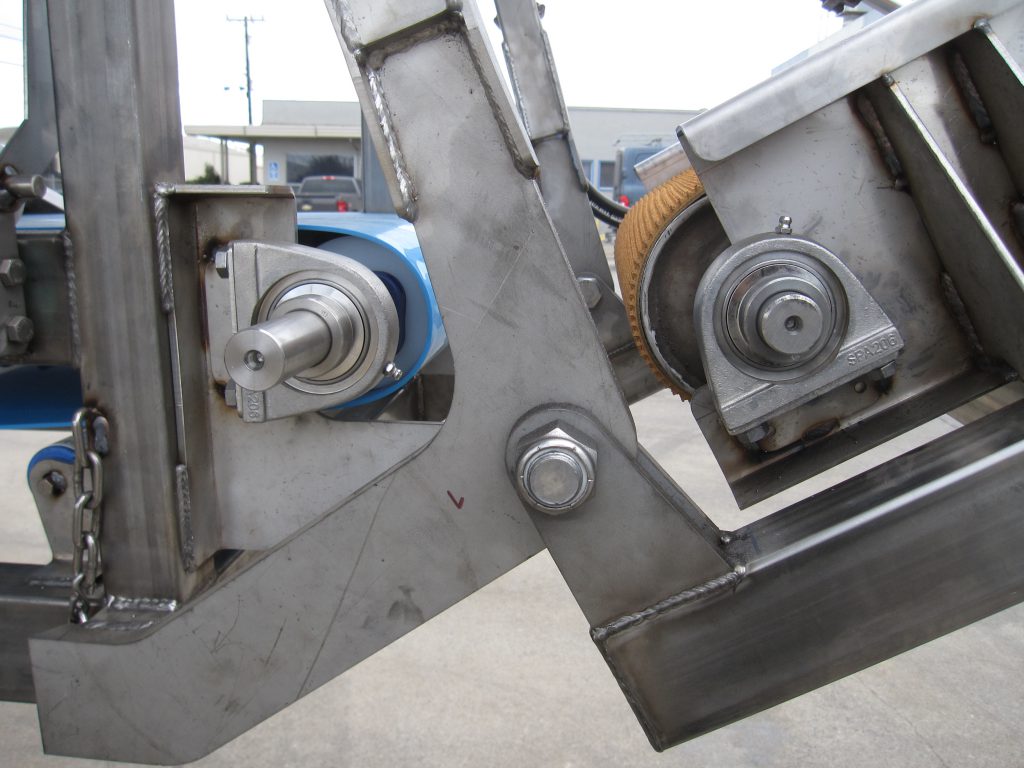

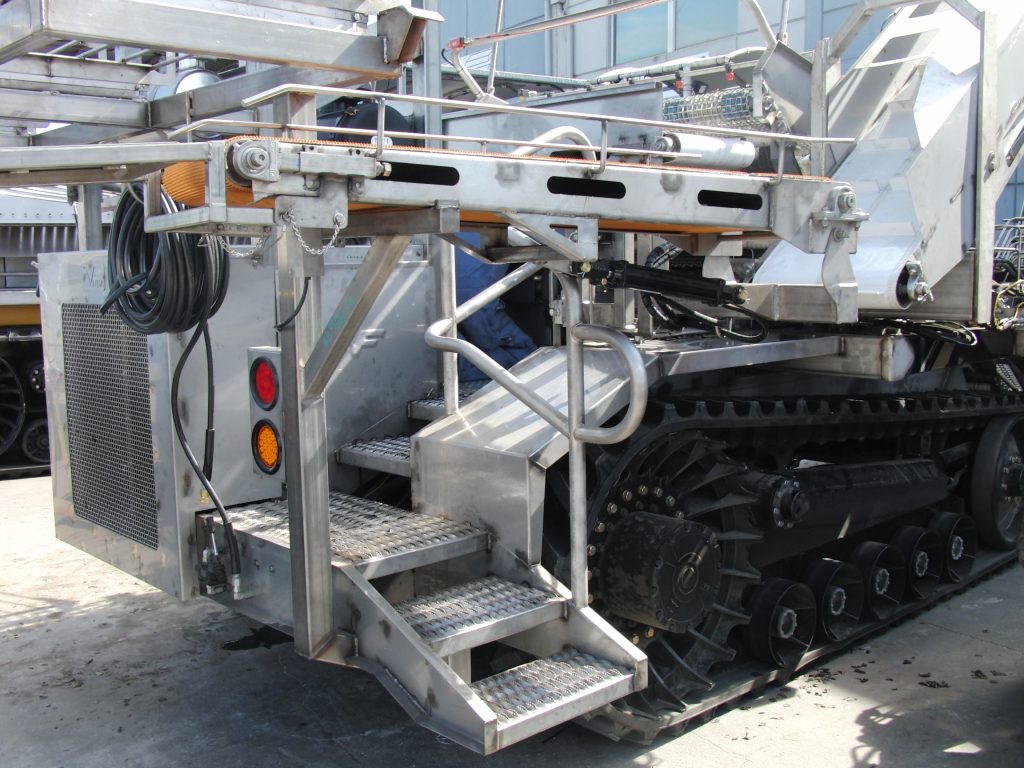

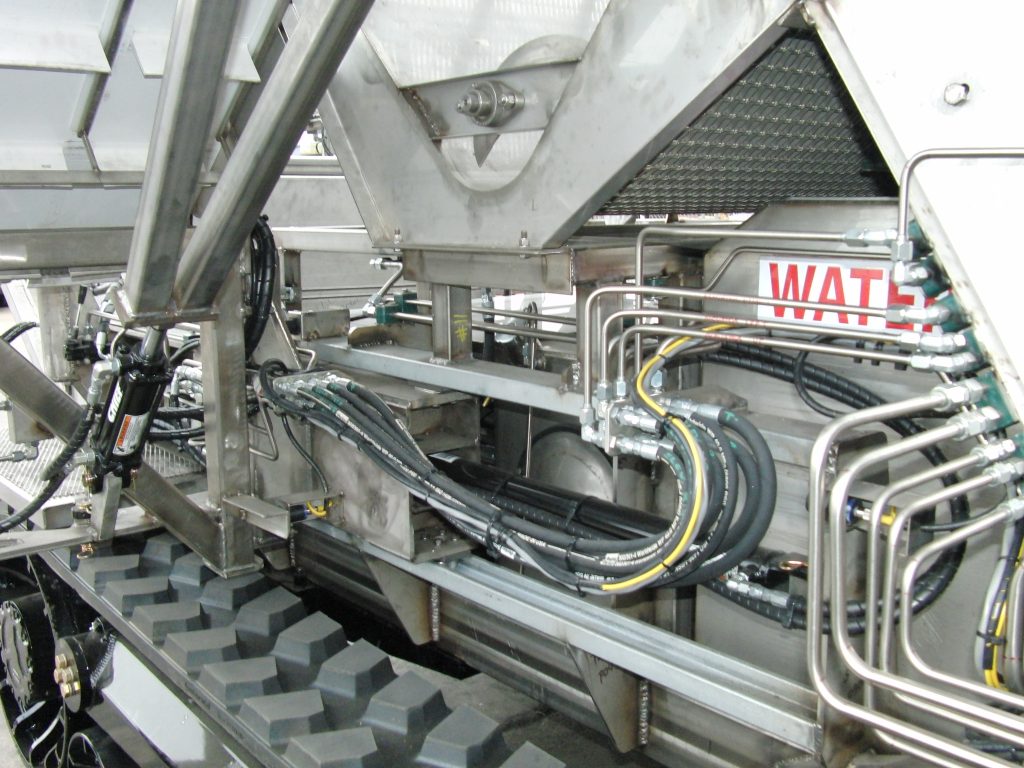

- Stainless steel construction

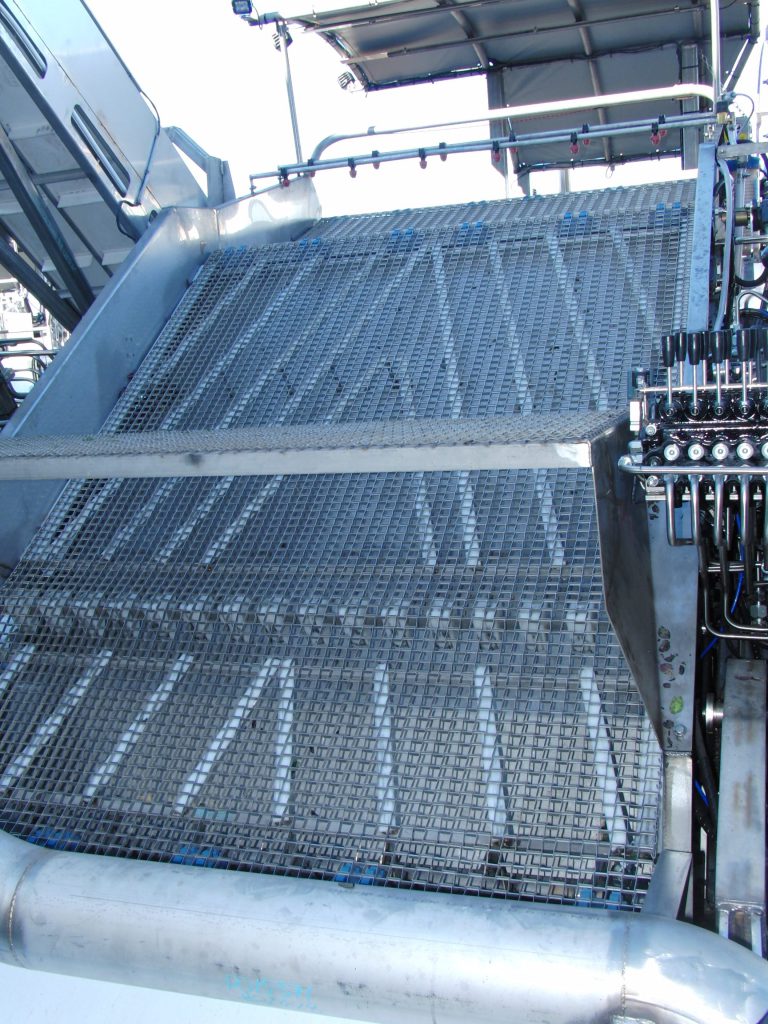

- Main frame conveyor will cover ten 40” beds

- Water spray nozzles, one per bed

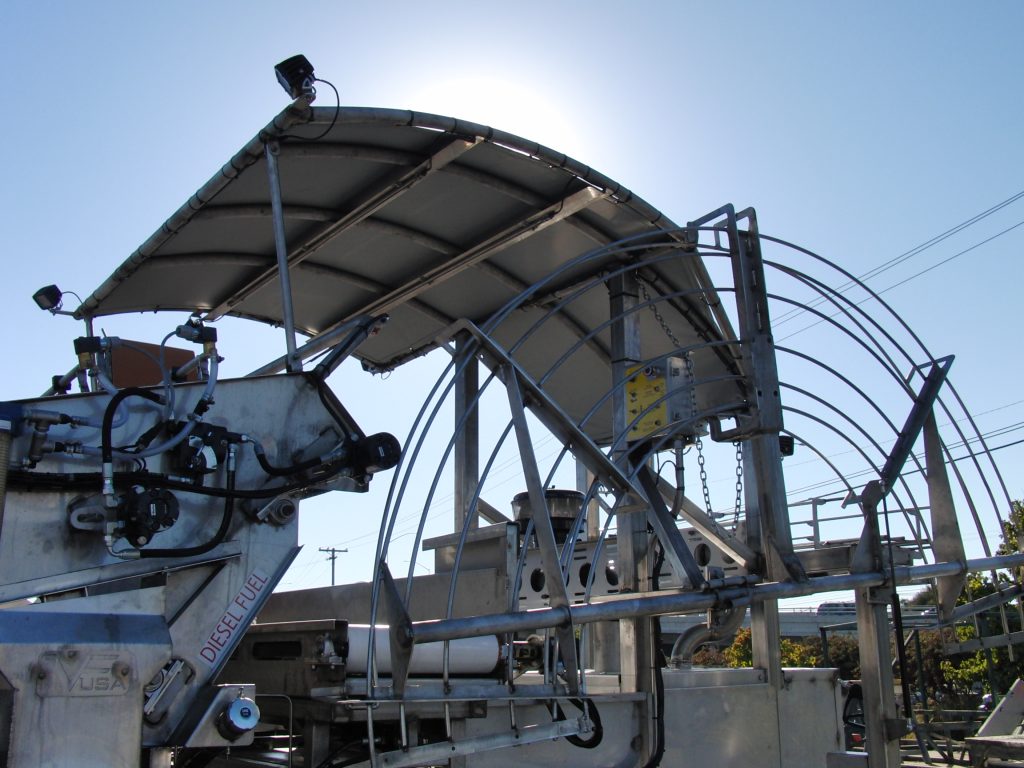

- Shade canopy over set up trays and packing racks

- Clip on set-up trays

- Box packing racks

- Duel Direction Main conveyor

- Two exit conveyors, both will have tan rough-top belting

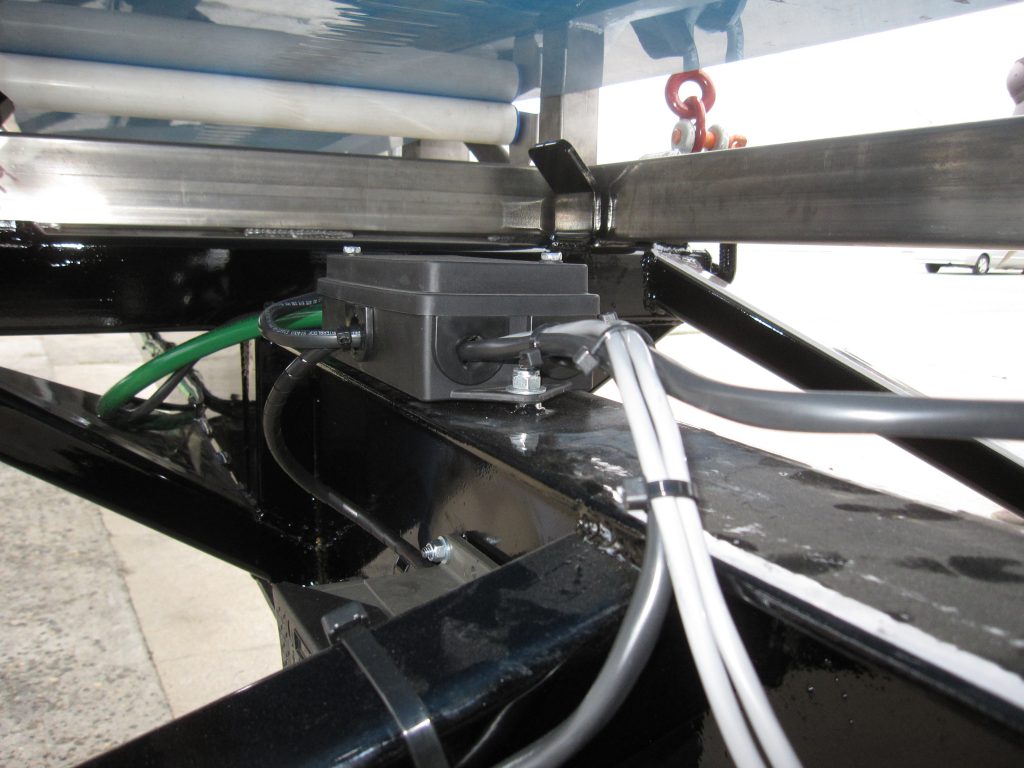

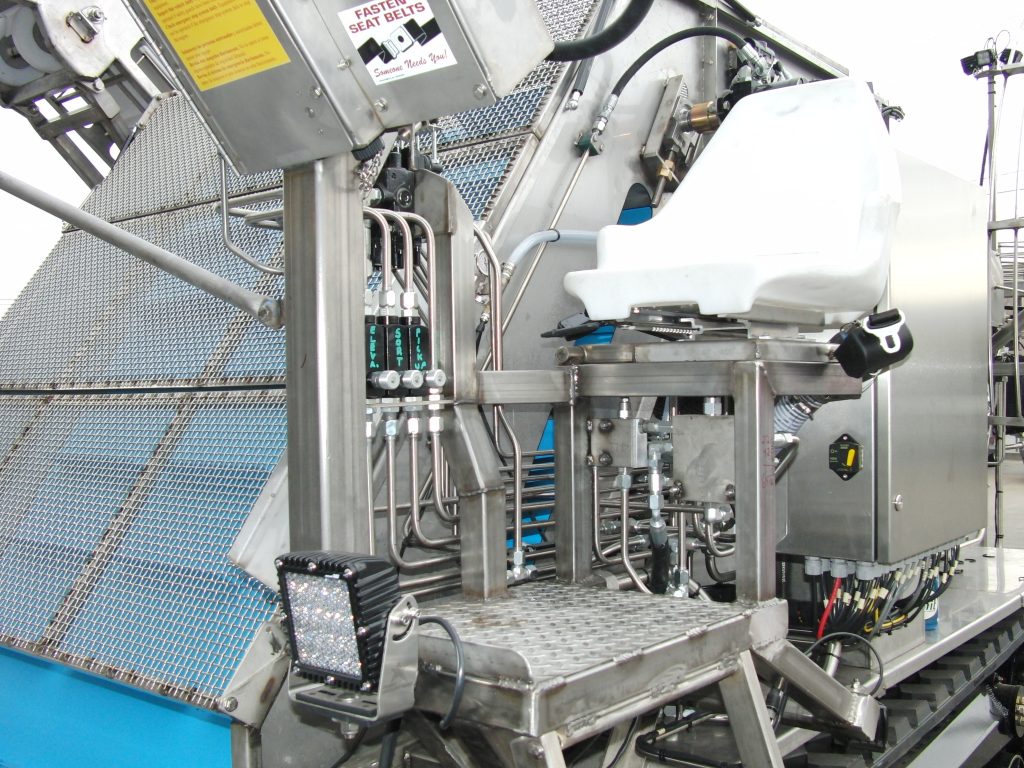

- Lights on machine for low light harvesting

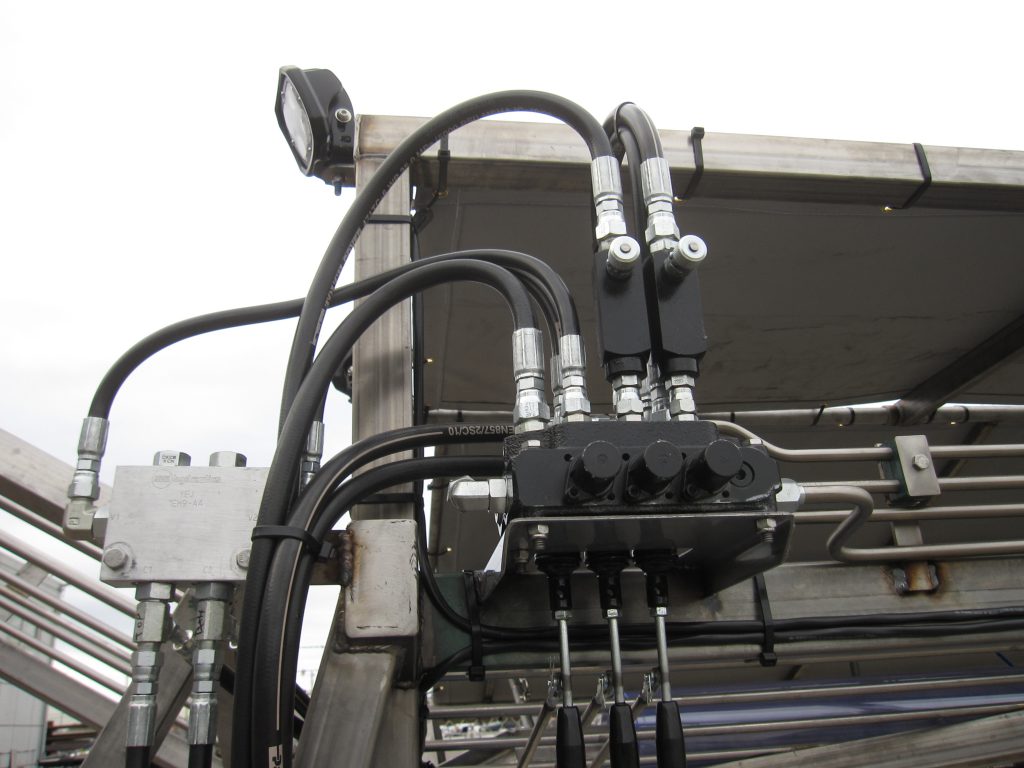

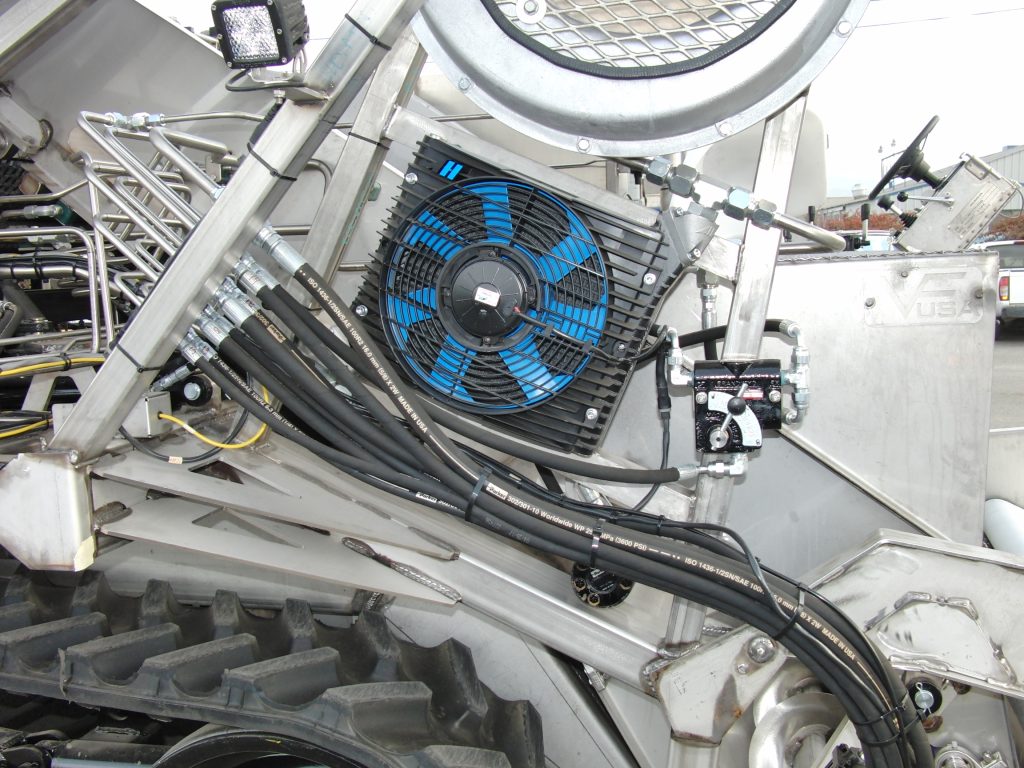

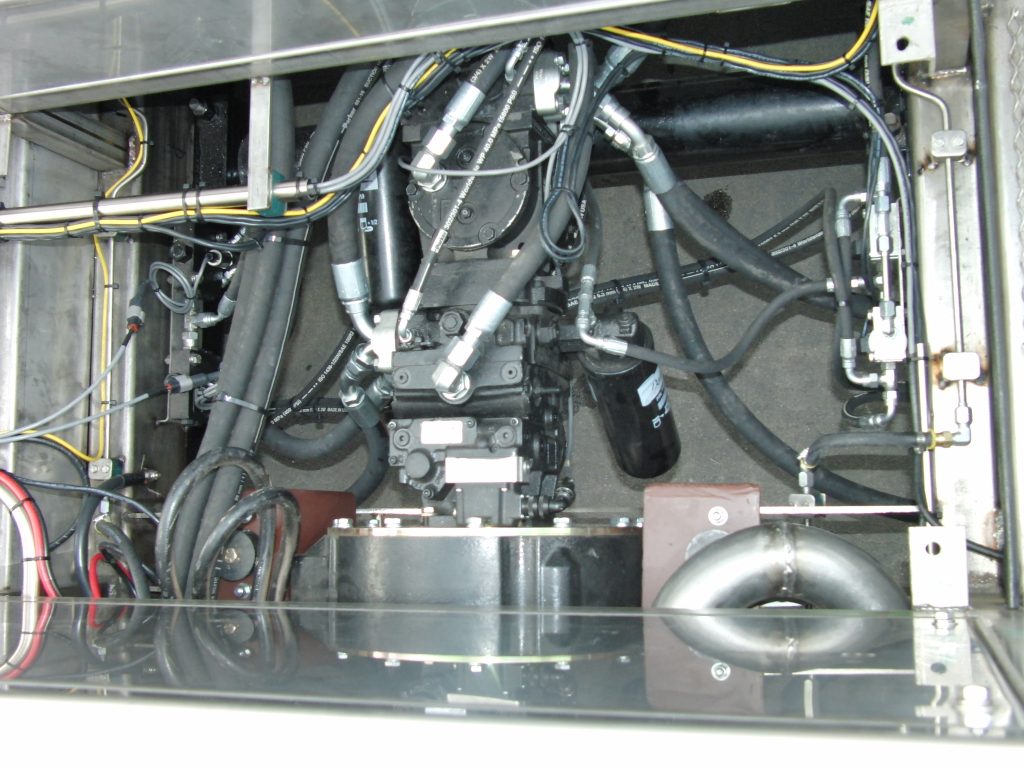

- A manual hydraulic control valve station on one end of the wing for:

a. Belt direction

b. Main belt speed

c. Tote exit belt speed

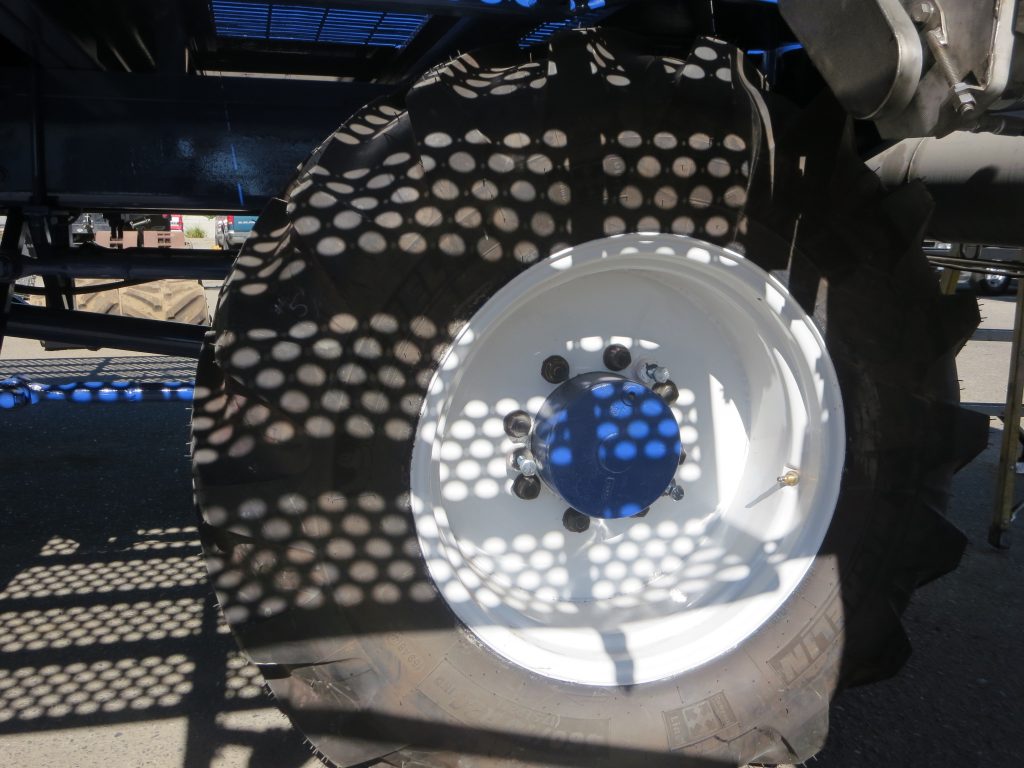

d. Tote exit tilt - The transport trailer will be mild steel construction with torque flex axles and electric trailer brakes

a. Tail lights on the trailer